Stereolithography (SLA) 3D Printing

What is Stereolithography (SLA) 3D Printing?

In addition to being the original industrial 3D printing process, Stereolithography 3D Printing (SLA) is one of the widely used additive manufacturing technologies. Many enterprises use SLA to produce complex models, concepts, and prototypes with optimal accuracy, high level of details, and excellent surface finish. At present, enterprises from various industries use SLA to 3D print models and prototypes with tight tolerances.

The jewelry designers use SLA 3D printing technology to conceive innovative jewelry designs with high precision and delicate geometries. Likewise, the medical industry uses SLA to produce anatomical models and microfluidics. Also, SLA is currently used widely for creating customized orthoses according to varying needs of patients. Many enterprises opt for SLA while they have to create realistic and detailed product models.

How Does SLA 3D Printing Work?

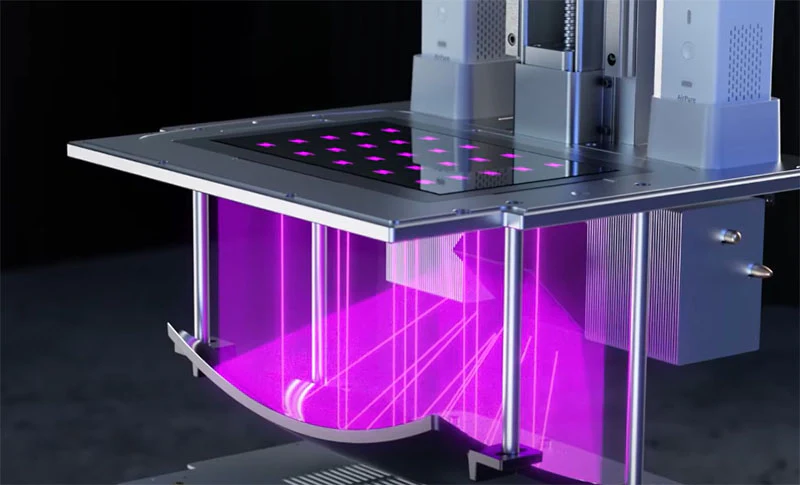

SLA is a laser-based 3D printing technology. It uses lasers as the primary light source to produce three-dimensional objects, models, or prototypes by curing photopolymer resins into hardened plastic. The SLA 3D printers deliver laser beans to the surface of the resin according to the CAD/CAM-based design diagram. As the laser beams hit the surface, the first layer of the object or model is formed.

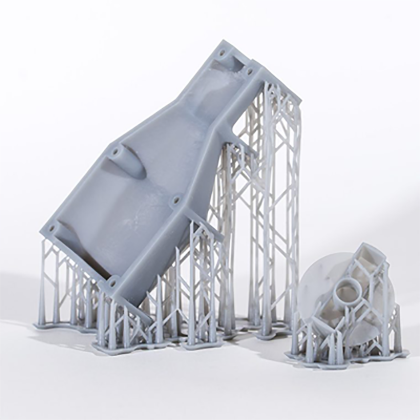

The SLA 3D printers keep adding new layers to the first layer by delivering laser beams to photopolymer resins. Once the 3D printing process is completed, the vat can be removed by raising the platform out. However, SLA requires 3D printing service providers to perform processing the 3D printed object by performing post-processing activities like painting, priming, smoothening, curing and support removal.

Why Should You Opt for SLA 3D Printing Technology?

No Support Needed

SLA produces three-dimensional objects by depositing thinner layers of resin. It uses fine laser beans to deposit layers ranging from 0.05 to 0.10 mm. The thinner layers make the 3D printing technology effective in producing prototypes with realistic finish and complex shapes.

Better Quality Output

SLA allows manufacturers to produce models and prototypes using a variety of 3D printing resins. The manufacturers can add smoother finish to the 3D printed objects simply by choosing the right form of resin.

Speed Up Processes

SLA produces three-dimensional objects using a substitution material like resin. But the parts and prototypes printed using SLA 3D Printing technology have functional surface quality.

Ready-to-use Products

SLA helps 3D printing service providers to deliver objects or models in 48 hours. The printers can easily save time and resources by avoiding the need to create a mold before starting the 3D printing process.

Why Arissta3D for SLA 3D Printing?

Types of Materials are used in SLA 3D Printing?

We believe in delivering high quality 3D printed objects and models by combining the right type of resins and customized 3D printing services. Also, we use reliable SLA 3D printers to complete the 3D printing process without any interruptions or disruption. Trust Aurum to print objects, products, models, and prototypes using SLA 3D printing technology efficiently.